Dear customers,

The Salinnova sales activities will be executed by Abacus Resale GmbH as of June 2022. If you have any inquiries for new products or questions concerning after sales, please do not hesitate to refer to Mr. Viera with the information in Contact.

Kind regards

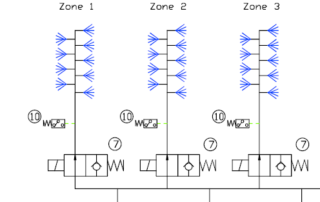

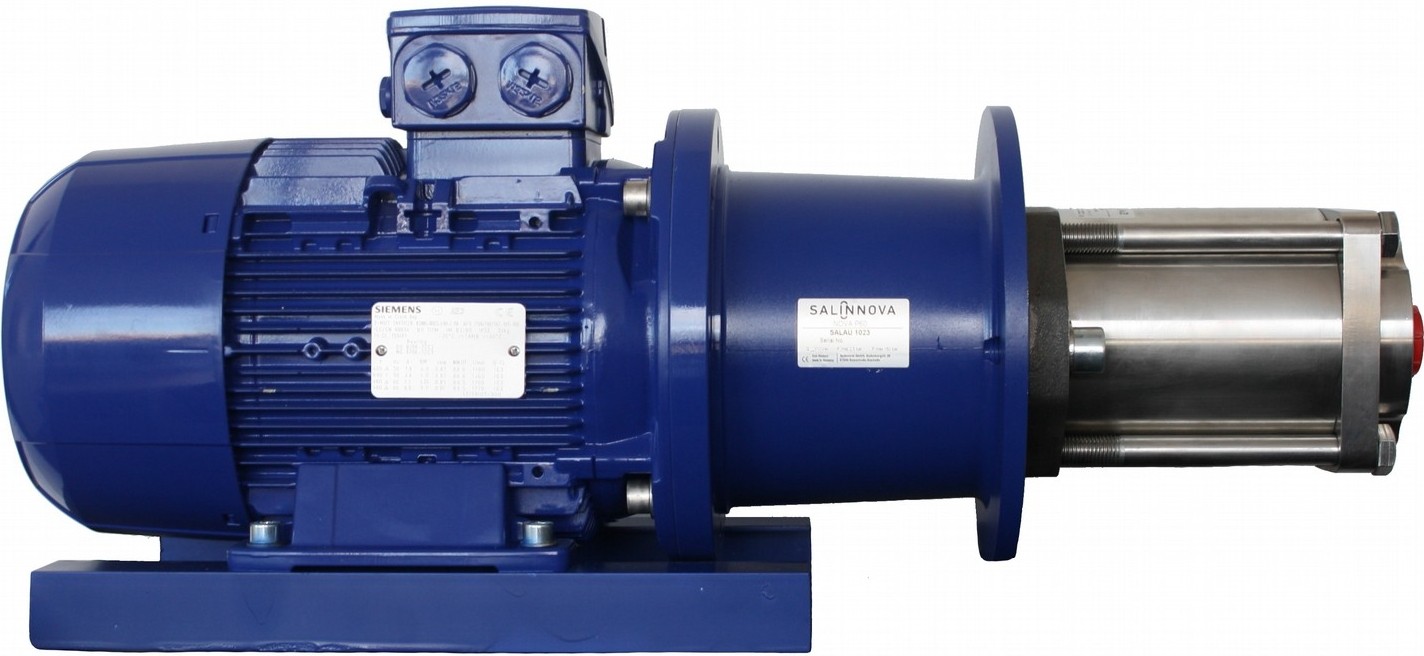

SALINO® Pressure Center

The most efficient high-pressure pump unit for RO systems

The fact that water resources are diminishing in many parts of the world challenges us to change the way we think about water. Especially in the field of seawater desalination, demand for innovative economical solutions is rising. It is in this field that Salinnova sets new standards with its SALINO® Pressure Center. It also means that Salinnova is leading the way with a technology that is both revolutionary and unique: an innovation that will bring fundamental changes.

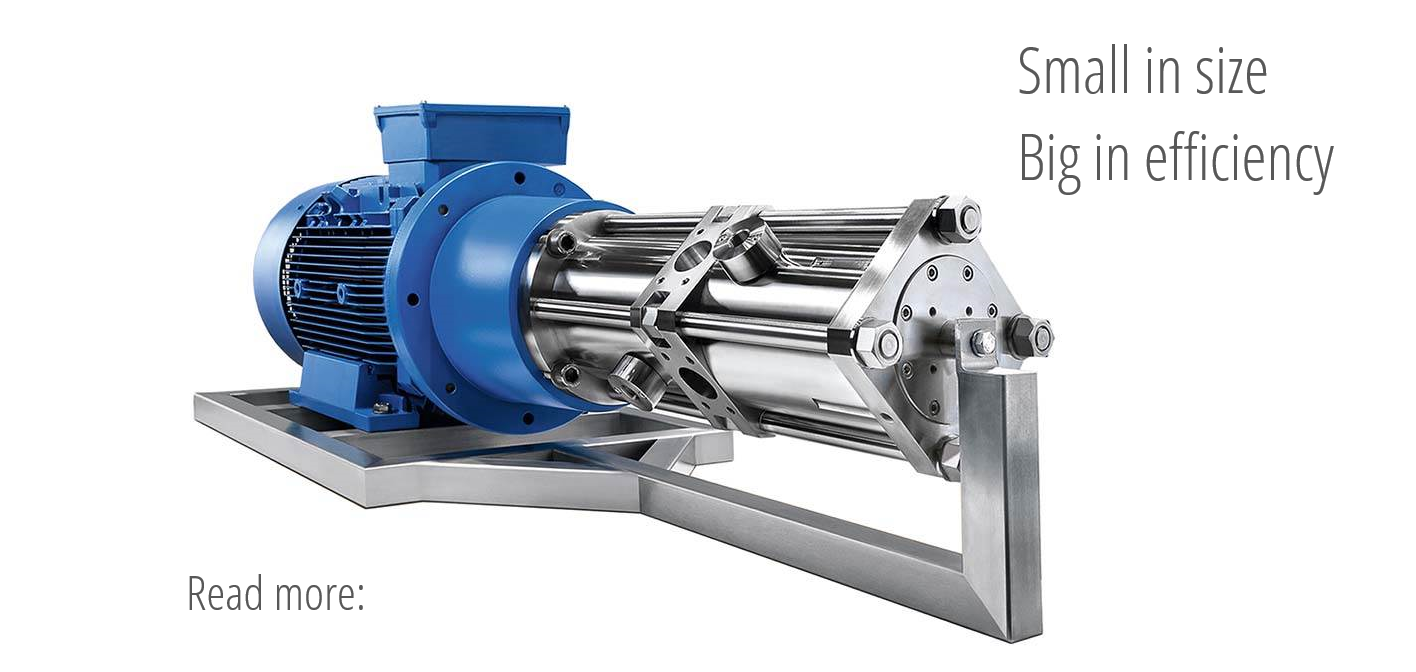

The SALINO® Pressure Center revolutionises seawater desalination by reverse osmosis. This is worldwide unique: The four main functions – the high-pressure pump, energy recovery device, booster pump and electric motor – are replaced with a single compact unit. As a result, it has the best energy efficiency and lowest life cycle costs in its class. It’s also easy to install and operate, and highly reliable to run. This makes our new SALINO® Pressure Center ideal for small and medium-sized systems in industry, ships and hotels.

SALINO® Pressure Center

High-pressure pump unit with integrated energy recovery for water treatment and desalination

Compact, economical, reliable:

pioneering 4-in-1 technology

In small to medium-sized desalination systems the SALINO® Pressure Center proves that greatness has nothing to do with size. The 4-in-1 technology combines all relevant components needed for pressure boosting and energy recovery in one RO system.

4-in-1 technology

Replaces high-pressure pump, energy recovery device, booster pump and electric motor.

Space-saving

Its extremely compact design and reduced number of components makes SALINO® Pressure Center ideally suited to decentralised use in containerised systems.

Low investment and maintenance costs

No need to match numerous individual components. Pipework is also reduced, and thanks to the use of forged parts the system is also less susceptible to corrosion.

Reduced operating costs

Maximum energy efficiency thanks to integrated energy recovery.

Easy to handle

Plug & desalt – installation, operation and maintenance of the compact unit is straightforward and fast. This also makes it less susceptible to errors.

Environmentally friendly and clean

Puts clean technology into practice via water-based lubrication that requires no oil.

Reliable and safe

Axial piston technology is tried and tested for use in high-pressure applications.

Applications and technical data

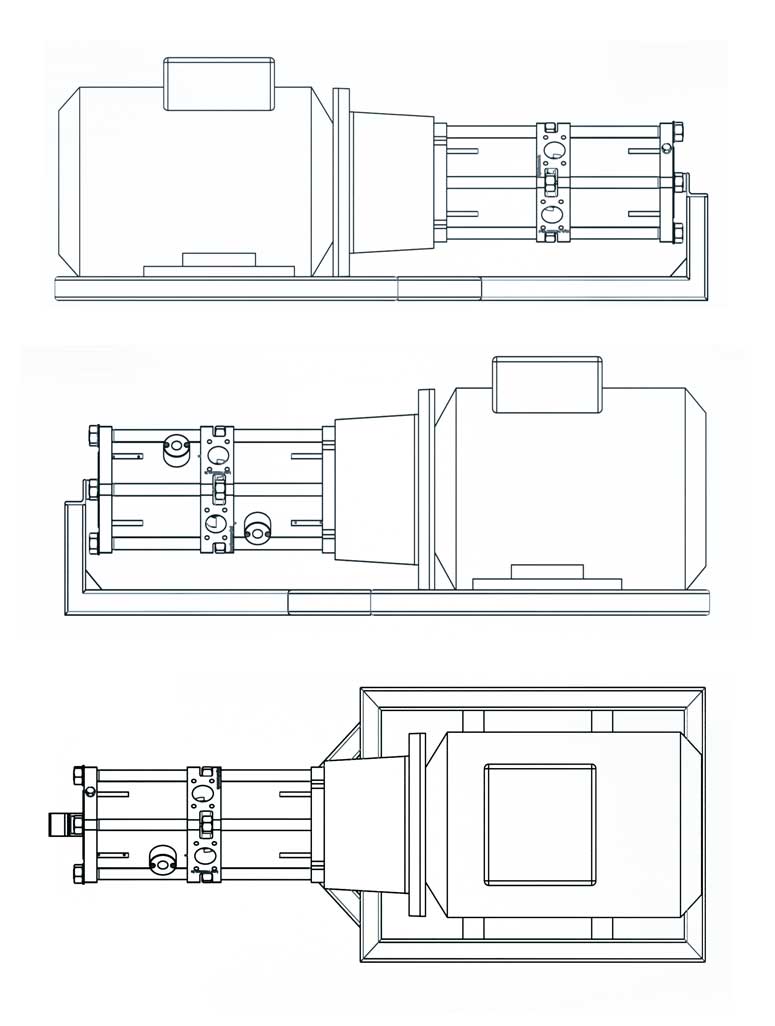

Construction

Horizontal, product-lubricated axial piston pump with integrated energy recovery.

Materials

• Duplex-stainless steel

• Super duplex-stainless steel

(on request)

Applications

• Oil and gas industry

• Industry

• Ships

• Tourism

• Agriculture

Technical data

Feed water flow rate: 70 m3/h / 243.8 gpm

Drinking water yield: up to 750 m3/d / 198129 gpd

Operating pressure*: 70 bar / 1015 psi

Motor rating: up to 75 kW / 101.9 hp

Temperature: up to +50 °C / +122 °F

* (higher operating pressure on request)

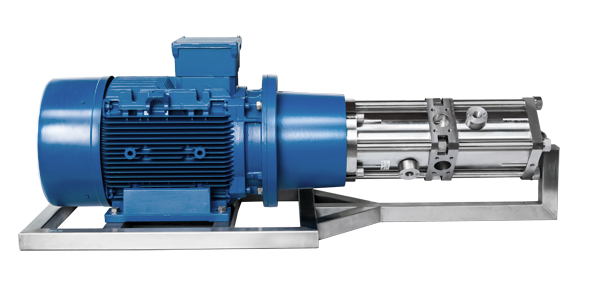

NOVA high pressure pump systems

Product advantages:

- Low operating costs through maximum energy efficiency – therefore rapid amortization

- Low investment and maintenance costs thanks to axial piston pump technology

- Plug & Run: The compact design of the system allows easy handling

- Environmentally friendly and clean thanks to the lubrication of the liquid passing through.

- Particularly suitable for Atex environments

Characteristics

The NOVA Series Axial Piston High Pressure Pumps are completely oil-free, clean and completely safe in all environments, including Atex environments.

Innovative material technology based on DUPLEX stainless steel ensures extremely high load capacity and service life.

The NOVA® pumps do without additional coolant or lubricant. All bearings are lubricated mediums. Oil change or relubrication is eliminated! Contamination of the liquid medium by lubricants is excluded.

The 9-piston design combined with direct 4-pole motor operation produces consistent output power and eliminates the requirement for output accumulation or pulsation damping. The pressure wave-free performance makes the product ideal in the respective application areas.